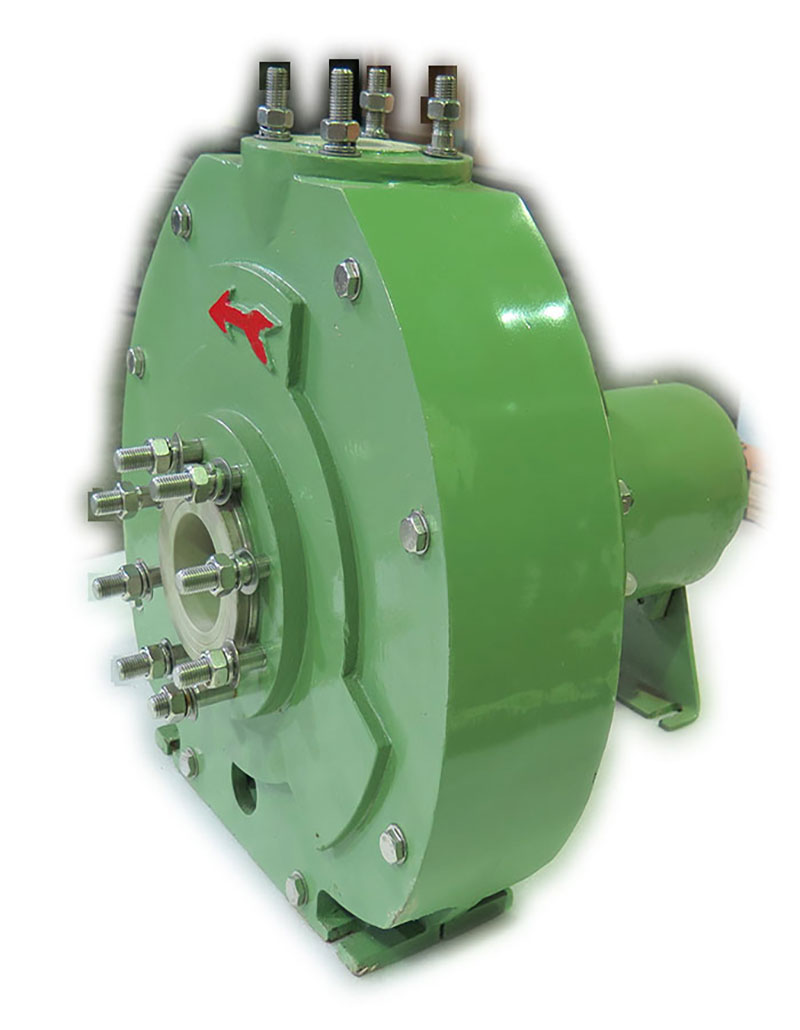

Acid Transfer Pump

Acid pumps are essential components in a variety of industrial processes and applications, where they play a crucial role in moving corrosive liquids and liquids with abrasive solids. In this comprehensive guide, we’ll cover everything you need to know about acid pumps, including how they work, their different types, and their benefits and limitations.

What are Acid Pumps?

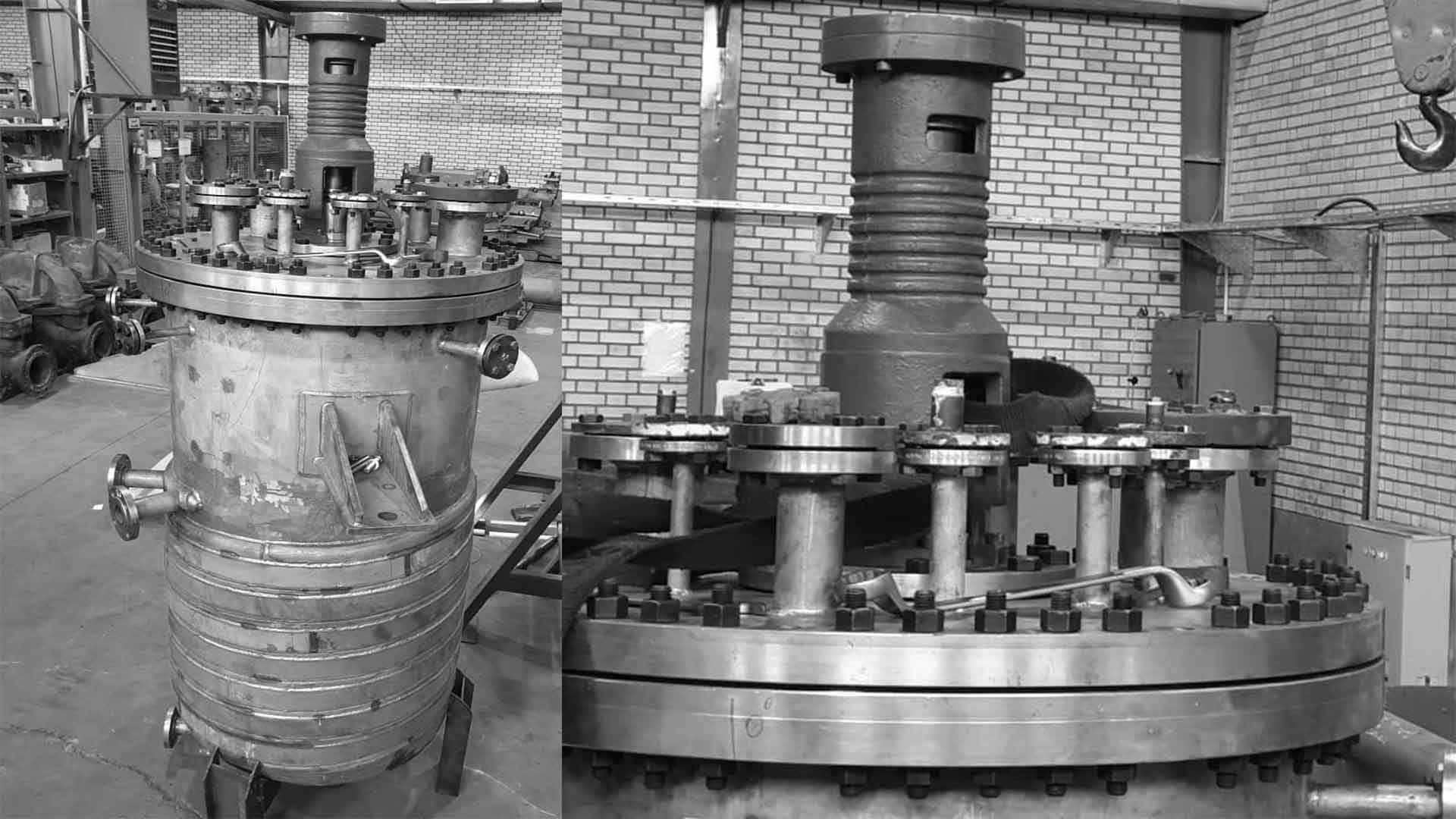

Acid pumps are pumps designed to handle corrosive and abrasive liquids that would damage or destroy regular pumps. These pumps are made of materials that can withstand the harsh chemical environment, such as stainless steel, duplex steels, and often plastic based polymers. The materials used in the construction of acid pumps depend on the type of liquid being pumped and the concentration of the corrosive material.

How do Acid Pumps Work?

Acid pumps work in much the same way as other pumps, using a rotating component to generate flow and pressure. The rotating component, typically an impeller or rotor, creates a flow by sucking the fluid into the inlet and expelling it out the outlet. In an acid pump, the rotating component is made of materials that can withstand the corrosive liquid being pumped.

Category: Pump

Description

Two main types of process pumps

There are two main categories of process pumps. These are Positive Displacement and Kinetic or Centrifugal. Within each of these categories, there are a variety of different types of process pumps.

Positive Displacement Pumps

A positive displacement pump moves fluid through a pipe by first trapping a certain amount of the fluid and then forcing it through the pipe or outlet. This can be done using several mechanisms, including reciprocating pistons, gears, lobes, vanes, progressive cavity, or an air-operated double diaphragm.

Positive displacement pumps are considered constant or continuous flow machines since they move the fluid at a constant rate regardless of pressure. It is extremely important that these pumps do not operate against a closed valve, as this could damage the pipe. To prevent this from happening, there must be a relief or safety valve on the discharge side of the pump.

Kinetic or Centrifugal Pumps

Centrifugal pumps are used in situations that require high volume flows. Unlike positive displacement pumps that create a continuous flow (or head), centrifugal pumps have a varied flow that is controlled via elbows, bends, valves, etc. within the pipe. The type and size of piping can also influence the rate of the flow.

While there are a variety of centrifugal pumps, they all work by converting rotational kinetic energy into hydrodynamic energy. They do this by creating flow and pressure through a vaned impeller. While designs vary, all centrifugal pumps include a case, impeller, shaft, bearings, and seal.

Determining the correct process pump for your operation

Generally speaking, you would use a positive displacement pump when you wish to move more viscous liquids at lower flow rates, and you would use a centrifugal pump when you wish to move more watery liquids at higher flow rates. Although this is not a hard and fast rule, it is a good guideline to start with.

Other considerations in choosing the type and size of a process pump include the type of liquid being moved, its viscosity, temperature, and its specific gravity. You will also need to consider your flow and pressure requirements as well as the length, diameter, and type of piping.