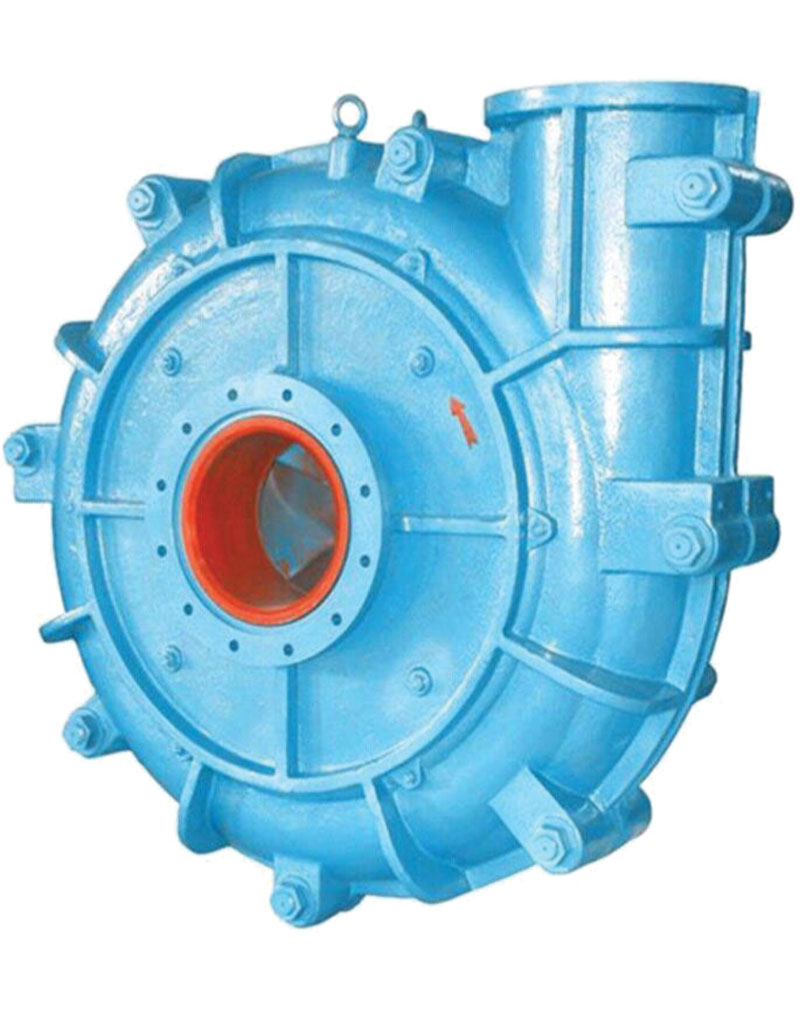

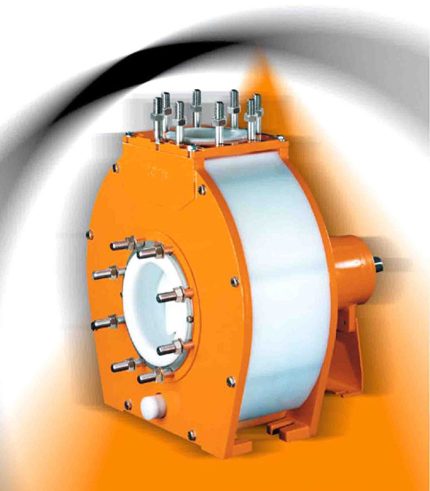

They are therefore designed in such a way that their wetted surfaces are hard-faced by deposit welding and the components exposed to wear such as rings, bushes, discs, casing inserts, impellers and all types of linings, can easily be replaced by new ones. They must therefore be reasonably inexpensive and consist of materials which are particularly resistant to abrasion or a combination of abrasion and corrosion.The operating requirements also include quick and easy pump dismantling and a reliable spare parts service for the replaceable parts. In addition to these pumps specifically developed for hydraulic solids transport, there is a number of centrifugal pumps that are, depending on their design and material properties, suitable for handling fluids of different contamination degrees and solids content