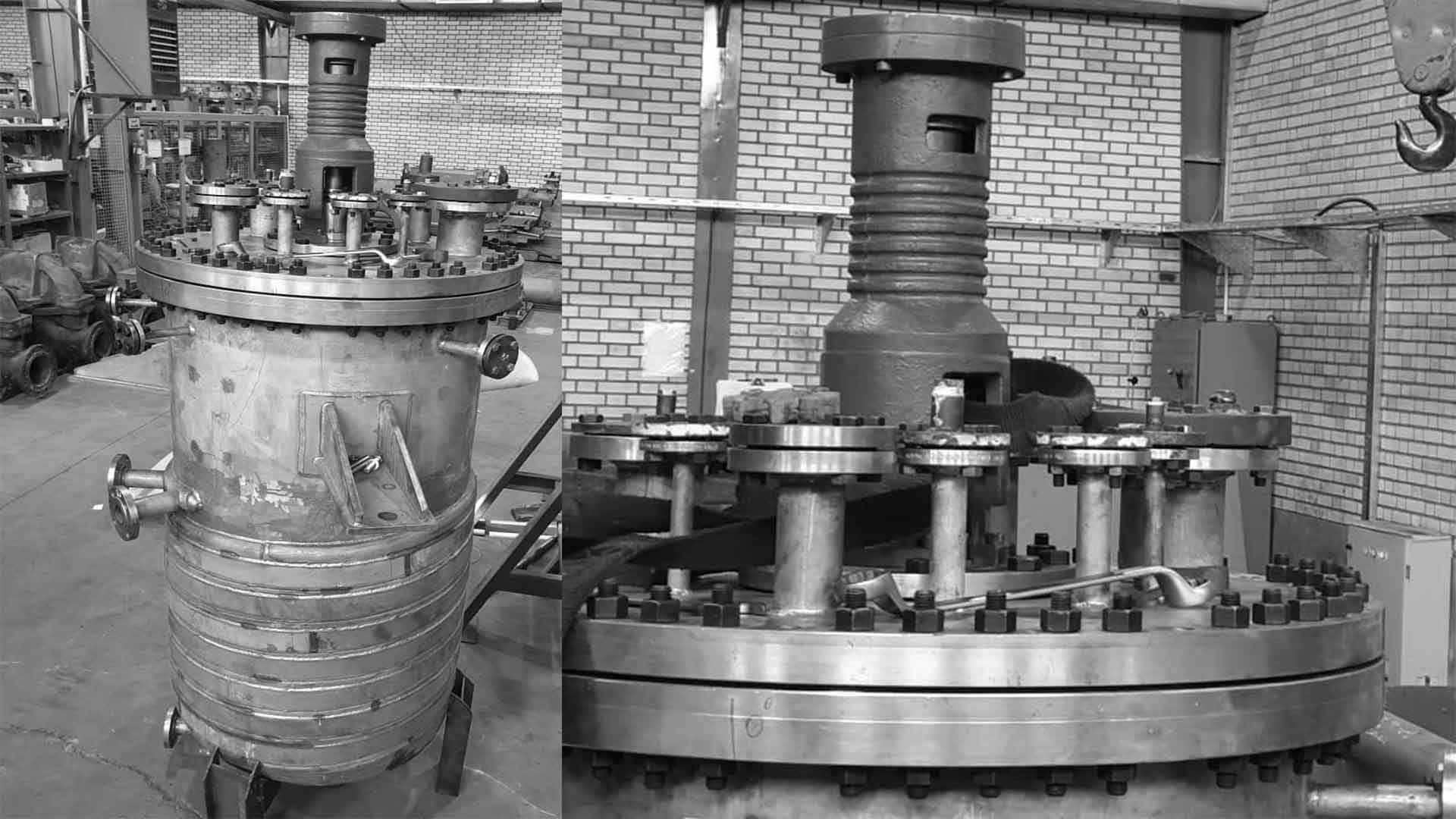

Bearing Housing

Bearings are subjected to a lot of wear and tear and require protection from temperature and pressure. A bearing housing does just that. As a cylindrical or rectangular casing, it encloses the bearings with a protective cast iron or steel barrier. The bearing housing is positioned at the pump’s base, where the shaft extends out from the main body of the pump. For the bearing housing to work properly, it has to be securely attached to the pump and also aligned precisely with the rotating shaft. Some housings may have lubrication channels so that the bearings receive the right amount of lubrication.

Diffuser

The diffuser is a component which effects a reduction in flow velocity and corresponding increase in static pressure whilst causing as small a loss as possible (see also Pressure loss).

Impeller

Pump Impellers – The Types & Their Impact

Of all pumping technologies centrifugal pumps are the widest known thanks to their efficient handling of many fluids. However, the specification of the right centrifugal pump for an application involves various considerations; one being the choice of impeller/s. But what is an impeller?

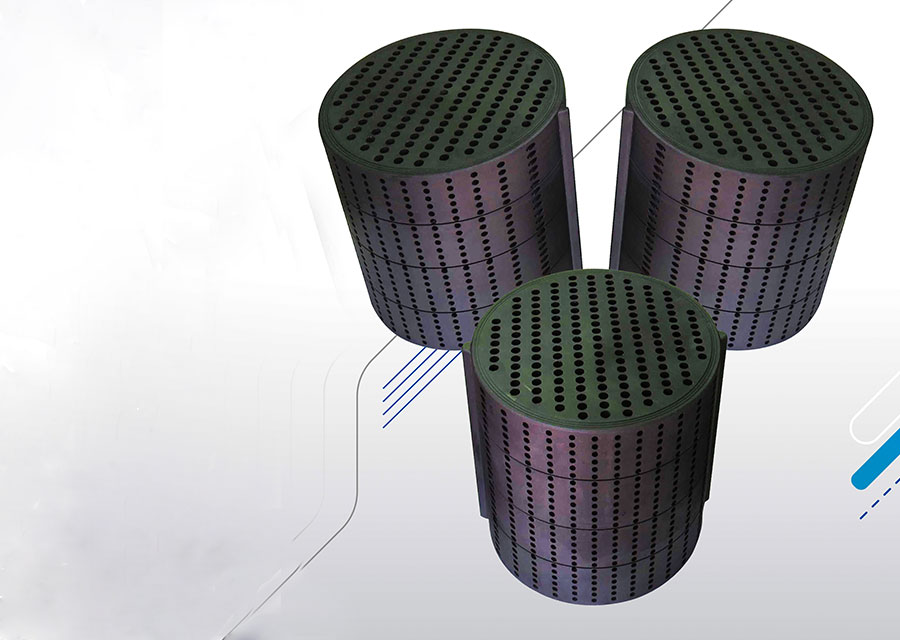

Wearing

Wearing ring is a part of equipment (pump) which is used for reducing the internal circulation of liquid in the casing of a pump. Wearing rings are always used in pairs, one is installed inside casing, another one is impeller wear ring mounted on the impeller body (last). Sometimes stepped type or double wearing ring are used. This type of wear ring is used for special types of applications like hazards or high pressure.

What is the use of Wearing in centrifugal pumps?

Wearings are used for many purposes, these are the following. Reduce the internal circulation of the liquid inside the casing of the pump. Maintain a gap (clearance) between casing and impeller end to reduce the vibration level. Save from rubbing each other, and help pump impellers rotate freely in casings with very small clearances maintained in pump casings.To prevent the liquid from entering from high pressure (discharge) into the low-pressure section side. Improve pump performance approx. (3–5 %) and also increase the life of pumps and impellers.